Polyurethane Rollers & Wheels

Polyurethane rollers are one of Precision Urethane's most popular product lines. We have over 49 years of experience as a urethane roller manufacturer and have accumulated a large selection of tooling which allows us to cast most customer orders with little or no tooling cost. With a full service CNC machining division to support new core machining or recovering / repair of existing rollers, we are able to provide a turnkey solution while controlling lead times and overall product quality.

Polyurethane Roller Information

- Drive rollers

- Idler rollers

- Feed rollers

- Conveyor rollers

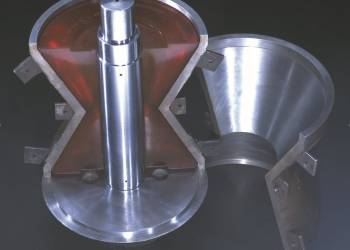

Urethane Roller Shapes

- Large urethane wheel casting in excess of 2000 lbs

- Urethane hourglass rollers

- Urethane straight rollers

- Urethane conveyor rollers

- Urethane radius rollers

- Slip-on urethane rollers

- Dual durometer urethane rollers

Urethane Roller Services

- Custom formulated compounds

- Custom sizes and lengths

- Hardness ranging from 20A to 75D

- Little or no tooling costs

- Used urethane wheel refurbishment

Polyurethane Roller Machining

Both our urethane roller molds and polyurethane (PU) roller cores are machined in our 10,000 square foot machining facility equipped with both CNC and manual machining equipment. Rollers and molds up to 50" in diameter can be processed in our state-of-the-art machining facility.

Cast urethane roller quality

Our design team works with each customer to figure the load bearing capacity of every pu roller, the necessary core design, and the selection of the right compound with the best physical properties for the design or application. In addition to urethane rollers, we manufacture solid rollers out of a variety of other materials, such as stainless, aluminum, bronze, UHMW or any other material a project may require. If tight tolerances are a priority, our experienced staff can hold +/- .0005 on bearing surfaces or on all dimensions of the urethane roller. We can also refurbish used rollers utilizing the existing cores at a fraction of the cost of buying new ones.