Quality Management Systems Process Flow

Our Quality Management Systems are designed to provide feedback from each process step to empower our team to address problems in real-time, while defining controls which drive part to part consistency and overall product performance. Our quality plan has been modeled after ISO-9001 standards. We have documented procedures and work instructions which drive detailed reports that are used by management to measure quality and performance, along with continuous process improvement. Metrology calibration and verification systems are maintained by our team daily to ensure all equipment is functioning properly. Our Team performs internal process audits and are adept at 8D corrective action analysis.

Our Core Structure

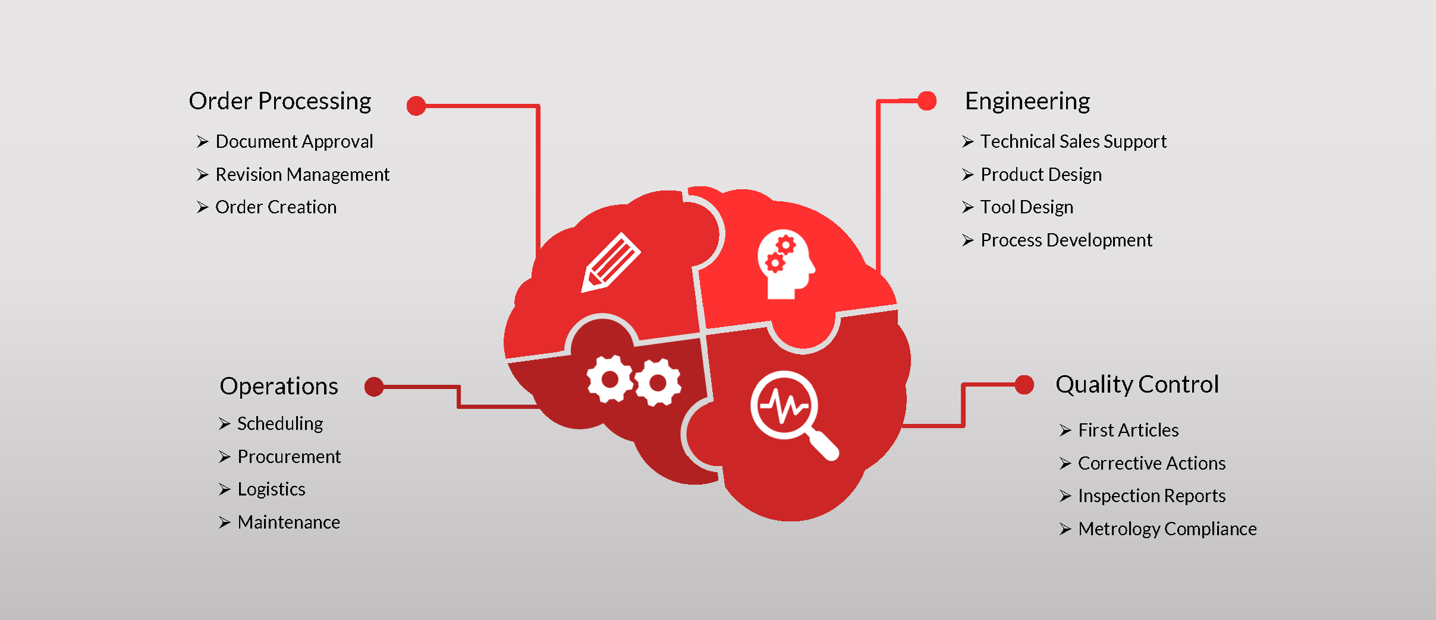

Precision Urethane’s organizational process flow is comprised of 4 different teams. Orders flow through each team driven by a robust ERP system and documents designed to provide concise clarity in each process step. Communication flows through a well defined report system and planning functions along with operational efficiency that are reviewed regularly by the management. Team meetings are held frequently to measure overall company performance and operational efficiency.

Order Processing

- Documental Approval

- Revision Management

- Order Creation

Operations

- Scheduling

- Procurement

- Logistics

- Maintenance

Engineering

- Technical Sales Support

- Product Design

- Tool Design

- Process Development

Quality Control

- First Articles

- Corrective Actions

- Inspection Reports

- Metrology Compliance

First Article Process

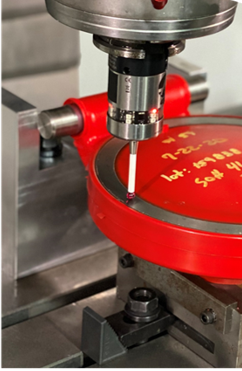

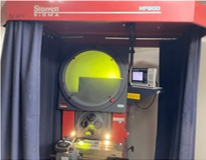

Each project has its own unique requirements. Our quality plan addresses the product function through interdepartmental communication to identify the essential performance characteristics and process monitor points to achieve part to part consistency. Each product we manufacture undergoes a full preproduction inspection and 100% dimensional analysis; we employ CMM and optical inspection technology, when necessary, in our first article process. We routinely supply inspection reports accompanied by first articles to the customer to perform fit checks on the first molded parts from production tooling we manufacture in the Machining Division.

Inspect The First Part

- Review production drawings and document inspection results

Management Review

- Evaluate inspection data and approve or send for customer review

Customer Review

- Submit inspection reports and results for approval / rejection / disposition

Management Evaluation

Approval = record first article documentation in ERP | rejection results in tool / part modification and requalification

Quality Control

In our Quality Control Department, we maintain quality measuring instruments that are calibrated regularly and verified daily. Every product is visually and dimensionally inspected to the customer's specifications. Then, the durometer and tolerance of the product is documented and filed for each day’s production. Our quality control team is committed to excellence. We continue to maintain a return rate of less then .01% on the products our customers have given us the opportunity to manufacture. We operate using an 8D corrective action plan with a formal RGA process.

Production Control

Throughout our manufacturing process, strict procedural guidelines are followed to obtain optimum physical properties for the products we manufacture. Our production control team monitors and records all metering machine calibration, programming, material lots, tool and equipment temperatures at the shift level to ensure process consistency. This enables us to achieve closer tolerances on our urethane products with tighter control over finished hardness.

Through our preventative maintenance program, our maintenance team ensures we have minimal down time in both the casting and machining divisions of our organization.