Maritime Structural Members Project Scope

- Geometry Optimization

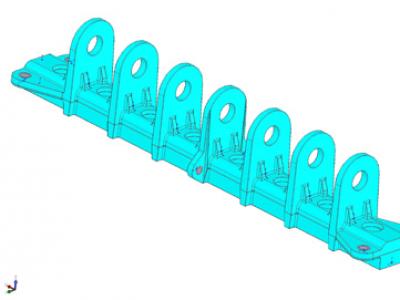

- Tooling Design

- Product Manufacturing

Geometry Optimization

Customer models were optimized with appropriate draft to remove the master from the tooling in the de-mold process.

Sheet Metal Fabrication

Sheet metal structures were designed and fabricated to minimize the urethane used in the tooling for the mold to cast the finished product.

Soft Prototype Tooling

Large parts were CNC machined as the master pattern which was inserted into the sheet metal structure to create the cavity, which formed the finished product. Tooling size is 36” wide X 36” tall X 155” in length.

Finished Product

Finished Product