Our Story

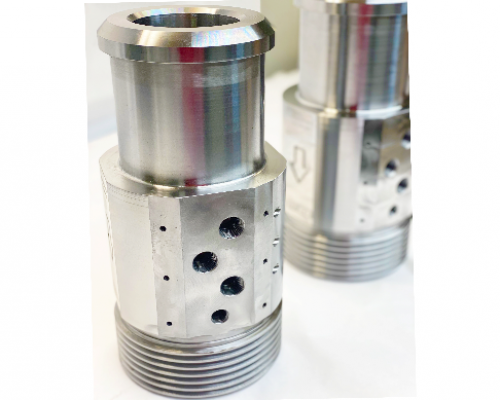

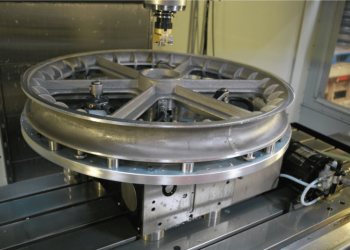

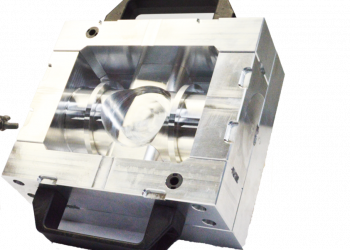

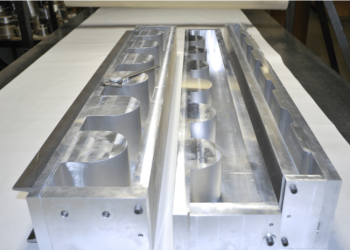

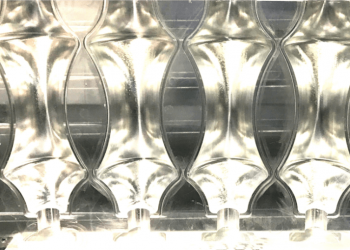

CNC milling is an extremely versatile machining process. It’s the use of multi-axis movements used in tandem with the diversity of tooling options which makes this process so valuable to our organization. We routinely machine complex geometries which require multi-axis contouring with deep pocketing, tight tolerances and critical surface finishes in our mold manufacturing operations. We are also very adept at designing custom work holding fixture systems in volume production operations. These operations, coupled with in machine real time part probe inspections, allow us to provide a wide array of CNC milling solutions.

Technical Information

| CNC Sawing | CNC Engraving | Metal Plating |

| CNC Turning | CNC Broaching | Metal Painting |

| CNC Threading | CNC Deburring | Comparator Inspections |

| CNC Knurling | CNC Drilling | CMM Inspections |

| CNC Milling | Metal Polishing | Heat Treating |

| CNC Boring | Volume Production Machining | Materials Sourcing & Purchasing |

4000lbs

Plastics

- Polyurethane

- Polytetrafluoroethylene

- Polycarbonate

- Polyvinyl Chloride

- Acetal (Polyoxymethylene Delrin)

- Polymethyl Methacrylate

- Acrylonitrile Butadiene Styrene (ABS)

- Polyetherimide

- Fiberglass

- Polyether Ether Ketone

- Polyethylene

Metals

- Aluminum

- Bronze

- Copper

- Brass

- Steel

- Magnesium

- Stainless Steel

- Zinc

- Titanium

+/-.0005

Programming/Tool Pathing

To effectively operate a CNC milling machine, tool paths must be created to define the cutting path for the tooling.

The goal of programming a CNC machine is to enable a machine tool to achieve automatic, precise and consistent cutting motion. To do this properly, the CNC requires a set of programming instructions call G codes which are a set of X,Y & Z coordinates which tells the machine how to machine the part. We use the Mastercam CAM system for programming our molds and finished parts. This process is performed by using the 3D model created in SolidWorks, then selecting the surfaces of the model and defining the tooling and the path each tool will take in the machining process. The CAM system will output a video of the toolpath to machine part.

High Speed Machining

This video is the result of the programming CAD /CAM video seen above. Machining operational cycle times have been optimized thru revisions in the feeds and speeds of each step along with specialized tooling including thru spindle drilling to allow for increased drilling speeds.

In-Machine Probe Inspection

Renishaw probe inspections are a valued added step in the CNC machining process for higher volume production machined parts. Custom macros are created to monitor tool wear and finished tolerance of each machining step in the process. This allows for in-process control over tolerance and greater machining accuracy on part to part tolerance.