First Article Procedures

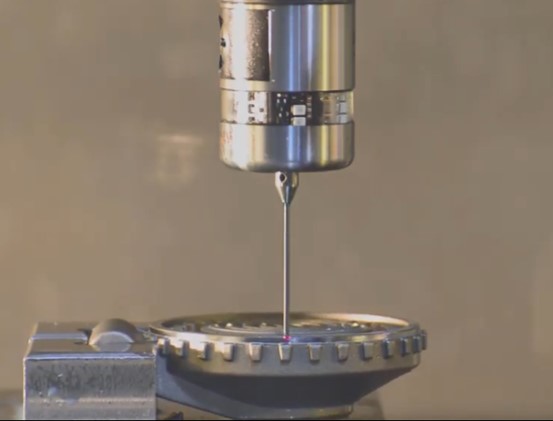

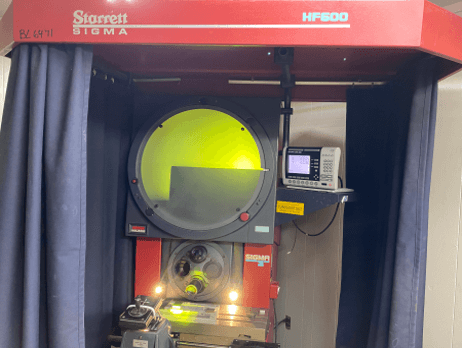

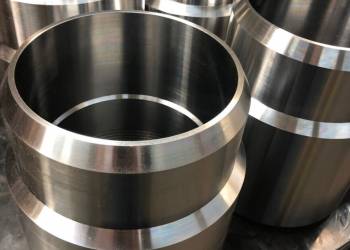

Each project has its own unique requirements. Our quality plan addresses the product function through interdepartmental communication to identify the essential performance characteristics and process monitor points to achieve part to part consistency. Each product we manufacture undergoes a full preproduction inspection and 100% dimensional analysis; we employ CMM and optical inspection technology, when necessary, in our first article process. We routinely supply inspection reports accompanied by first articles to the customer to perform fit checks on the first molded parts from production tooling we manufacture in machining division.

Production Control

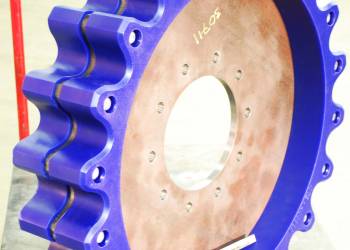

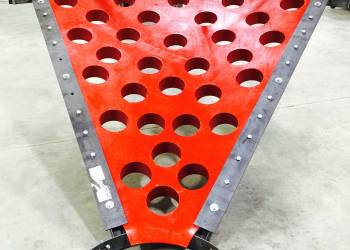

Throughout our manufacturing process, strict procedural guidelines are followed to obtain optimum physical properties for the products we manufacture. Our production control team monitors all mold temperatures to ensure stable shrinkage factors enabling us to achieve closer tolerances on our urethane products. Each day all of our processing and curing equipment is calibrated and monitored to see that the proper stoichiometry is achieved for every cast.

Quality Control

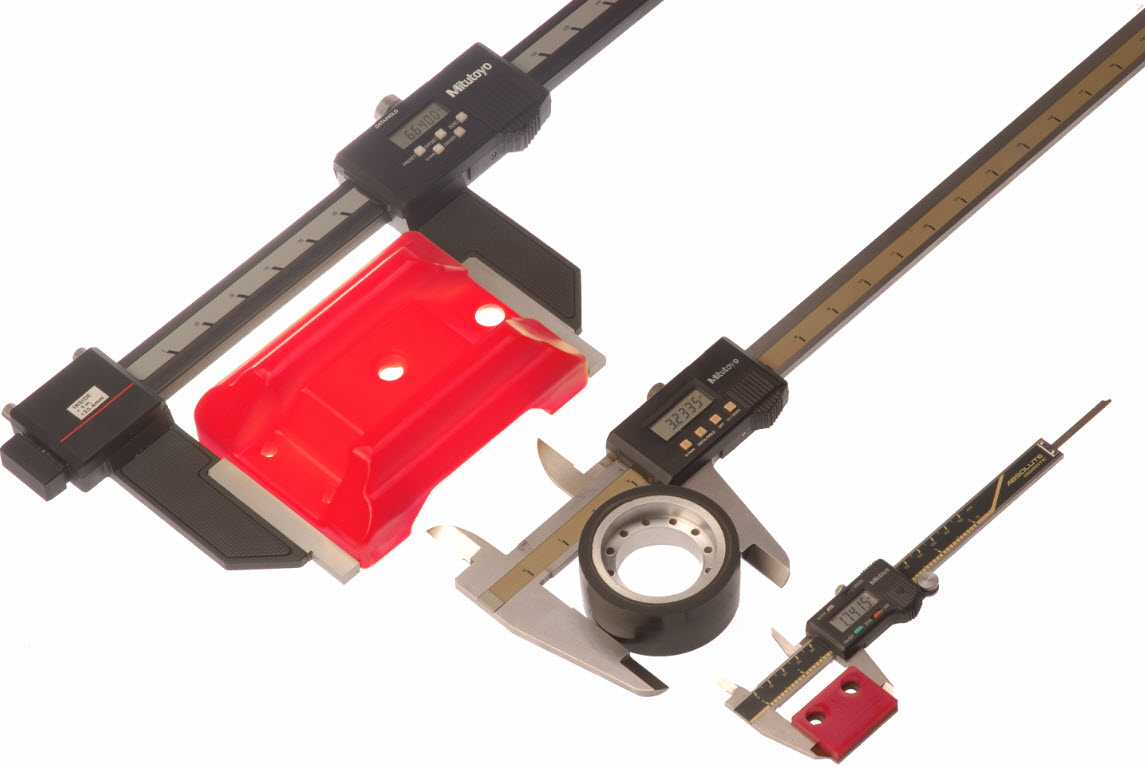

In our quality control department, we maintain quality measuring instruments that are calibrated and checked each day. Every product is visually and dimensionally inspected to the customers specifications. Then, the durometer and tolerance of the product is documented and filed for each days production. Our quality control team is committed to excellence. We continue to maintain a return rate of less then .5% on the products our customers have given us the opportunity to manufacture. We archive this information for each shift's production to maintain total documentation throughout our manufacturing process.

Material Certification

As part of our quality plan, we can provide material certifications on all of the components we use in our products. We will include the manufacture date(s), lot number(s), and the post cure date. We archive this information for each shift's production to maintain total documentation throughout our manufacturing process.