Urethane Concrete Molds

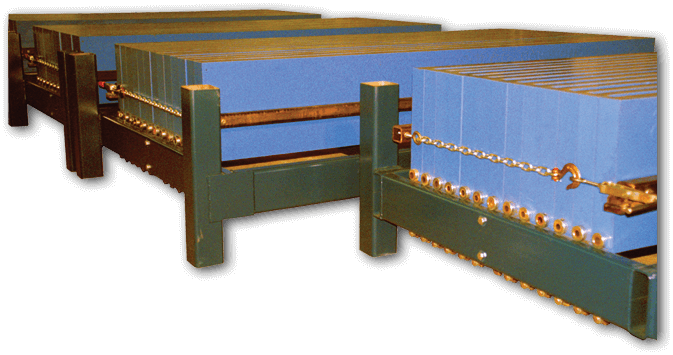

Can't find the concrete molds to fit your projects requirements? Precision Urethane can create polyurethane molds based on your requirements or personal artwork. We will work with you to fully customize the mold you need. Cast concrete molds offer flexible solutions for a variety of concrete processing applications, or your own DIY projects. Urethane's outstanding ability to adhere to metal, and our total fabrication facilities allows our concrete molds to encapsulate metal reinforcing substructures while maintaining a soft durable exterior to aid in the de-mold process.

Why use Urethane for Casting Concrete Molds?

Liquid rubber (polyurethane) is a great way to make durable, perfectly smooth molds for concrete. It is typically less expensive and has a high abrasion-resistance than silicone molds. Urethane concrete molds do not shrink and come in a range of hardness. Their high abrasion resistance and strength make it possible for them to be used again and again.

Urethane molds offer incredible flexibility. Concrete molds can easily release from intricate details, including undercuts once the concrete has set. This flexibility allows for both large and small applications: from small DIY crafts such as candles and soaps, to large industrial architectural elements. Other possibilities include sinks, drainboards, soap dishes, countertops, architectural elements, glass fiber reinforced concrete (GRFC) concrete statues, edges, and many other products.