Cast Urethane Product Design

The moment we receive an RFQ from our customer, our goal is to ensure we truly understand the unique requirements of each customers application and provide a solution which exceeds expectation. Our sales engineering process has been designed to define the right project scope based on the following:

- Product Life Cycle: Application Operating Conditions must be considered as the first step in the process to determine if the product should be a polyester or polyether system. Chemicals, operating temperature and UV exposure can all impact the material selection process. Polyester systems are great in demanding applications, but will break down over several years do to hydrolysis causing premature product failure. If they do not wear out before breaking down, polyether based systems should always be considered in applications where product wear life will exceed the life cycle of a polyester based system.

- Application Load Conditions: A clear understanding of the physics involved in each application is essential in defining the right mechanical properties of the polyurethane system and associated material hardness. Once these are clearly defined we can then apply our knowledge of which type of system will perform best in the application and how to create a formulation which targets these specific mechanical properties using various stoichiometry adjustments, along with additives introduced into the system at time of processing. See our technical data page for more information.

- Dimensional Requirements: A review of the finished dimensions of the finished part is a critical step in manufacturing and must be clearly defined in the sales engineering process. The end tolerance of the part will have an impact on the overall part cost and manufacturing method, which can add additional costs to maintain tight tolerances when an application may not necessarily require it. Conversely, secondary machining operations may be required to maintain finished tolerances to meet customer requirements. Interfacing with our customer to understand this balance can be a value added step to reduce product cost and is an essential part of our sales engineering process.

- Estimated Annual Usage and Target Price: This is a critical piece of the overall project scope and is essential in providing our customers with the right ROI (return on investment) on production tooling and will also impact the overall product cost. In a molding operation, the number of molds or the number of cavities in a mold will have a large bearing on the overall part cost. Conversely, the more molds or cavities a project requires to meet customer demand, the higher the tooling cost. Understanding this dynamic between tooling cost and the overall impact on part cost and associated production capacity can ensure lead times are balanced with overall project costs.

- Manufacturing Process Flow: Tolerance, size, shape and production volume are all key factors in determining the correct tool design and manufacturing process used to mold the finished product. For more information about our manufacturing processes, see our polyurethane product manufacturing page.

Typical Project Scope

- Prioritize the engineering properties and design characteristics critical for your application.

- Material selection: We can suggest a compound and use a variety of curatives and additives to increase or decrease specific engineering properties which are critical to performance in the application.

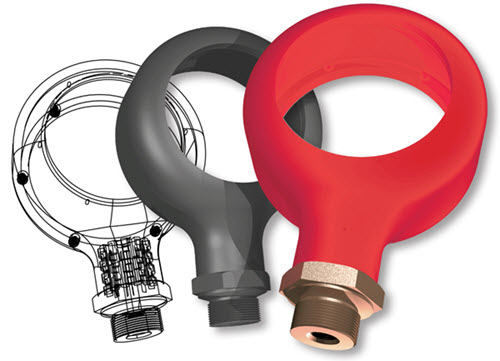

- Manufacture a prototype: In many situations, we can use in-house tooling and machine the prototype without large tooling costs. We can also use the latest stereolithography to create a “soft tool” to cast a prototype part.

- Prototype Testing: We routinely submit several different compounds to our customers whose products see extreme environments for testing in hopes of extending the life of products we manufacture.

- Make any necessary changes to the compound or design to eliminate any concerns noted in testing.

- Submit a physical properties data sheet to be added to the drawing.