Cast Urethane Products

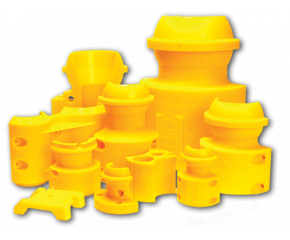

Precision Urethane has manufactured countless urethane parts and products used in many industries worldwide. We provide cast polyurethane manufacturing solutions for high and low volume production. Manufactured using high-performance resins, curatives and additives, our cast polyurethane products can be manufactured in almost any hardness or shape. This is possible through a number of manufacturing processes which employ state-of-the-art technology at each processing step. With experience in highly customized products, we welcome complicated projects and difficult applications.

Precision Urethane manufactures custom molded polyurethane products which span a wide range of industrial applications. Our scope of services were developed to handle large and small scale design and prototype projects, to high volume contract manufacturing agreements.

Manufacturing History and Experience

We have over 49 years of experience in custom polyurethane molding. Over the years, we have cast some of the most intricate and difficult products in the Polyurethane industry. We bring a fearless spirit and a long history of outstanding quality, product performance and customer service to meet the ever changing needs of our customer base. Please review some of our past successes in our projects portfolio.

Urethane Processing Technology

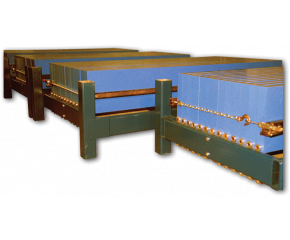

We utilize a number of molding process technologies such as: transfer compression molding, spin casting, open casting and vacuum casting to low pressure injection molding. We manufacture products ranging from wheels to wipers in sizes from 1 gram to 2,000 lbs. We use state-of-the-art casting machines with outputs ranging from 200 grams per minute to 125 pounds per minute. We carry a wide array of urethane material systems and additives which allow us to not only meet performance requirements of our customers, but accomodate pricing as well.

For more information on the typical processing methods that we use in our manufacturing process, or to view more of the cast products we manufacture, please visit the pages below.

Typical methods used to mold polyurethane products

Liquid polyurethane is poured into an open mold and placed in a heated compression press and pressure is applied to extrude the material into all areas of the mold.

Liquid polyurethane is poured into an open mold which is placed in an oven or on a heated table.

Liquid polyurethane is poured into an open mold which is spinning. This process is designed to remove any air entrapped in the pouring process.

Liquid polyurethane is injected into a closed mold which is fastened together with bleed gates designed to allow the air to bleed out of the mold in the injection process.

The performance criteria of polyurethane products is measured using data obtained from tests designed to isolate an individual characteristic of the finished material. These tests are typically run according to an established set of standards provided by an accredited organization such as the American Society for Testing and Materials (ASTM) who define the procedure in detail (www.astm.org). There are many different tests and procedures which can be performed on polyurethane materials. The primary function of these procedures is to establish a set of predictable performance properties that can be used to design a product which will meet a predetermined set of performance requirements. Precision Urethane has developed a significant base of polyurethane material data which we use to determine the correct material for application conditions.

Examples of the cast urethane products we manufacture:

Polyurethane Rollers

Polyurethane rollers are one of our most popular product lines. Our large selection of tooling allows us to cast many customer orders with little or no tooling cost.

Learn More

Polyurethane Concrete Molds

Precision Urethane can create polyurethane molds used for concrete molding based on your requirements or personal artwork.

Learn More

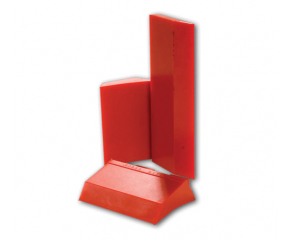

Polyurethane Pads

Precision Urethane can custom fabricate a product to specific chemical make-up & durometer in order to provide the best shock absorption performance.

Learn More

Polyurethane Bushings

Our polyurethane bushings and bearings are used in frictional or corrosive environments and can reduce down time and replacement costs.

Learn More

Polyurethane Pipeline Products

We have produced many different shapes and sizes of cups, scrapers, guide rollers, and other products used in inspection units worldwide.

Learn More

Polyurethane Rings

Our polyurethane rings are manufactured from high performance prepolymers in order to reduce down time and replacement costs.

Learn More

Polyurethane Cable Products

Our in-depth knowledge of compounds with a low coefficient of friction and abrasion resistance led to success in the urethane industry.

Learn More

Polyurethane Nozzles

Whether dispensing sand, water or other abrasives, polyurethane’s unique ability to resist impact wear makes it an ideal solution for high pressure applications.

Learn More

Polyurethane Scraper Blades

Polyurethane scraper blades are flexible, non-corrosive, chemical resistant, and can tolerate and withstand demanding conditions.

Learn More

Cast Polyurethane Diaphragms

We can supply cast urethane diaphragm samples in a number of hardnesses for testing and evaluation.

Learn More

Polyurethane Clamping Products

We manufacture polyurethane clamping products and bend limitation products used in a number of cable industries.

Learn More

Multi-Hardness Urethane Products

Multi-hardness or dual-durometer urethane products offer unique solutions which can be incorporated into a broad range of applications.

Learn More

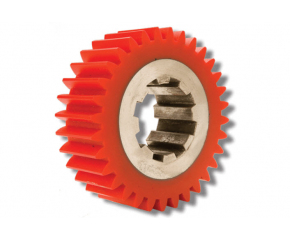

Polyurethane Gears & Sprockets

Our large cast polyurethane gears are impact, chemical and abrasion resistant, yielding properties that cannot be achieved using rubber or steel.

Learn More

Polyurethane Seals

Our polyurethane seals are molded to tight tolerances and can be designed to withstand extreme conditions.

Learn More

Polyurethane Tube

Polyurethane tubes are available in custom diameters, lengths, hardnesses and colors with little or no tooling costs.

Learn More

Polyurethane Sheaves & Pulleys

The cast urethane sheave and pulley products we manufacture range from 1” to over 48” diameter.

Learn More

Polyurethane Liners & Lining

Our polyurethane liners are custom manufactured to solve wear issues related to bulk transport of many types of materials.

Learn More

Polyurethane Couplings

Polyurethane couplings are impact, chemical and abrasion resistant, yielding properties that cannot be achieved using rubber or steel.

Learn More

Polyurethane Protective Covers

Urethane's abrasion resistance and its flexibility allows it to perform when molded into a variety of geometric shapes.

Learn More

Polyurethane Bend Stiffeners

We have manufactured many different bend stiffeners used on cables, flexible pipelines and umbilicals in dynamic applications where constant protection is required.

Learn More

Polyurethane Bridge Bearing Pads

We have manufactured bearing pads used in bridges and roadways world wide. Polyurethane bridge bearing pads have clear advantages over traditional rubber bearing pads.

Learn More